Profile Extrusion Line Popular Products

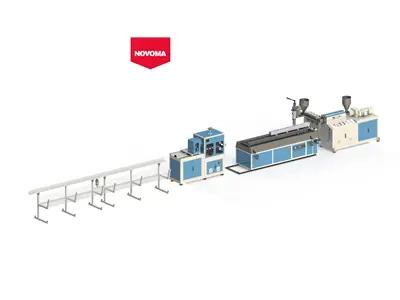

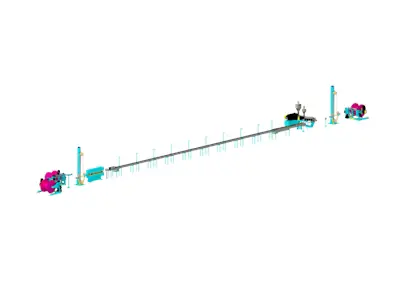

Profile Extrusion Line

A profile extrusion line is an industrial production line that allows various plastic, metal, or composite materials to be continuously and precisely shaped. This technology enables the serial production of fixed-section products such as pipes, rods, profiles, and sheets by melting and shaping materials. Profile extrusion lines are commonly used to work with plastic materials such as PVC, PE, PP, and ABS in industries such as construction, automotive, furniture, and electrical. These machines, widely used in various industries, allow profiles to be produced quickly in durable and precise shapes.

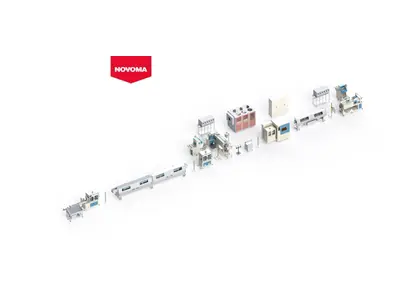

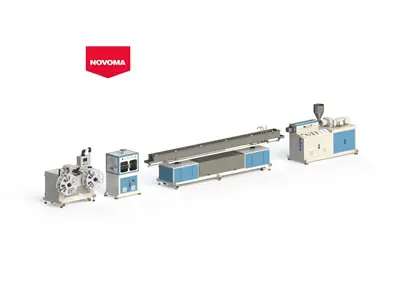

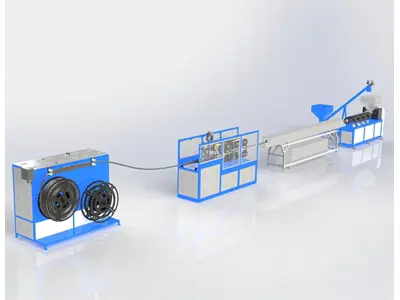

A profile extrusion line mainly consists of an extruder machine, molds, cooling systems, pull units, and cutting machines. The process starts with granules of raw material being heated and melted in the extruder machine. The molten material then takes the desired profile shape with the help of specially designed molds. The cooling process preserves the form of the material, and the profile produced is continuously cut to the desired lengths at the end of the line through pull units. This production method stands out with high precision, repeatability, and low waste rates.

In the category of profile extrusion lines, machines with different capacities and functions are available. Compact lines suitable for small and medium-sized enterprises offer effective solutions in limited spaces, while extrusion lines designed for large industrial enterprises can be adapted to high-capacity production processes. Additionally, the molds and extruder capacity of the line can be customized according to the size and complexity of the profile being produced. This flexibility makes the profile extrusion line a preferred production technology in many sectors.

Profile extrusion lines offer cost advantages and production flexibility to businesses. Especially in large-scale productions, these machines minimize material waste while providing energy efficiency to produce high-quality products. Equipped with advanced automation systems and control technologies, profile extrusion lines allow users to manage production processes more efficiently and accurately. Therefore, profile extrusion lines are an ideal solution for businesses aiming to produce high-quality and precisely shaped products.

Profile Extrusion Line Prices

Profile extrusion line prices vary depending on the line's capacity, technology used, level of automation, and components of the production line. Compact extrusion lines designed for small and medium-sized enterprises are generally found in more affordable price ranges, while high-capacity and large-scale industrial lines are offered at higher prices. Factors such as extruder capacity, characteristics of the molds used, and the production speed offered by the line also play a significant role in affecting prices. Additionally, advanced technologies that provide energy efficiency, automatic control systems, and special design molds can increase prices. Depending on the size of the investment and the degree of customization of the line, prices can vary widely. When selecting a profile extrusion line that meets production needs, businesses can make the best choice by considering both capacity and long-term production costs. Profile extrusion line prices can range from {price range} on average.

To meet your need for a new or used profile extrusion line, you can purchase from reliable manufacturers or authorized suppliers through makinaturkiye.com and also get support from authorized services.